Reduce Scaling

One of the primary challenges that industries face with their water systems is the buildup of scaling and corrosion.

Whether in an industrial boiler, a cooling tower, or similar water treatment or delivery system, mineral deposits can build up and form a dense layer.

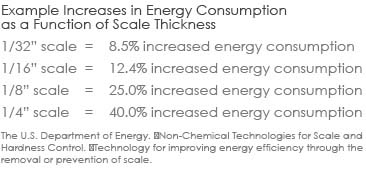

These deposits include calcium, magnesium, iron, copper, silica and other elements. In a boiler tube, for example, this buildup can impede heat transfer.

Corrosion too can contribute to deposits, which results in metal damage to the system.

Challenges with Evaporation

When water evaporates, minerals typically left behind will concentrate in the remaining water.

If this concentration exceeds the saturation point, these minerals deposit on the internal surface of a cooling system, for example, and cause scaling build-up.

Cooling Towers

Typical cooling towers are designed to cool the heated water that passes through the system, removing the heat from the refrigerant that cools a building.

It is estimated that at least 60 percent of the problems associated with these cooling towers are caused by scaling.

The H2O ENERGIZER Industrial Solution

Omni Enviro’s H2O ENERGIZER Industrial activates the water source, transforming water’s molecular structure through the use of magnetic resonators.

This safely and effectively changes the structural characteristics of water, preventing mineral deposits to bond.

This, in turn, prevents scaling and build-up which can damage the system and lead to costly maintenance and repair costs.

More Impacts

For an overview of specific technical and economic effects related to boiler water, cooling systems and related applications, click here.